BG Motor has been a DC motor manufacturer and AC motor supplier for 30+ years.

The Power Of AC Gear Motors: A Comprehensive Guide To Understanding Their Functionality

Are you curious about the inner workings of AC gear motors and how they can enhance the functionality of various devices and machinery? Look no further! In this comprehensive guide, we will delve into the power of AC gear motors and provide you with a detailed understanding of how they operate and the benefits they offer. Whether you are a novice or a seasoned industry professional, this article will equip you with the knowledge you need to fully grasp the capabilities of AC gear motors. Keep reading to discover the fascinating world of AC gear motors and unlock their potential in your projects!

- The Basics of AC Gear Motors: What You Need to Know

AC gear motors are essential components in a wide range of equipment and machinery, playing a crucial role in converting electrical energy into mechanical power. In this comprehensive guide, we will delve into the basics of AC gear motors and provide a detailed understanding of their functionality.

What is an AC gear motor? An AC gear motor is a type of electric motor that incorporates a gear reduction system to achieve the desired speed and torque output. These motors are commonly used in applications where precise control of speed and torque is required, such as conveyor systems, industrial machinery, and robotics. The AC in AC gear motor stands for alternating current, which is the type of electrical power that these motors use to operate.

One of the key components of an AC gear motor is the gear reduction system. This system consists of a series of gears that work together to reduce the speed of the motor and increase its torque output. By adjusting the size and number of gears in the reduction system, manufacturers can customize the motor to meet specific performance requirements.

The functionality of an AC gear motor is based on the principles of electromagnetism. When an AC current is applied to the motor's stator windings, a magnetic field is generated that interacts with the rotor to produce rotational motion. The gear reduction system then translates this motion into the desired speed and torque output, allowing the motor to drive a wide range of mechanical loads.

There are several key factors to consider when selecting an AC gear motor for a particular application. These include the motor's power rating, speed and torque requirements, duty cycle, and operating environment. It is important to choose a motor that is well-suited to the specific needs of the application to ensure optimal performance and longevity.

In addition to their functionality, AC gear motors offer several advantages over other types of electric motors. They are highly efficient, reliable, and require minimal maintenance, making them ideal for use in demanding industrial environments. AC gear motors are also available in a wide range of sizes and configurations to suit a variety of applications.

In conclusion, AC gear motors are versatile and essential components in a wide range of equipment and machinery. By understanding the basics of AC gear motors and their functionality, you can make informed decisions when selecting a motor for your specific application. Whether you are designing a new system or replacing an existing motor, choosing the right AC gear motor is crucial to achieving optimal performance and efficiency.

- Advantages of AC Gear Motors in Various Applications

AC gear motors are a crucial component in a wide variety of industrial applications due to their numerous advantages. In this comprehensive guide, we will delve into the functionality of AC gear motors and the specific benefits they offer in various industries.

One of the key advantages of AC gear motors is their ability to provide precise speed control. This is particularly important in applications where a consistent speed is required, such as in conveyor belts or automated machinery. AC gear motors can easily be adjusted to maintain a constant speed, ensuring efficient operation of the equipment.

Another advantage of AC gear motors is their high torque output. This makes them ideal for applications that require heavy lifting or moving of large loads. Industries such as automotive manufacturing, material handling, and robotics rely on the high torque capabilities of AC gear motors to ensure smooth and reliable operation.

AC gear motors are also known for their durability and reliability. With proper maintenance, these motors can withstand harsh operating conditions, such as extreme temperatures, high humidity, or dusty environments. Their long lifespan and minimal maintenance requirements make them a cost-effective solution for many industries.

In addition to their robust construction, AC gear motors are highly efficient. They are able to convert electrical energy into mechanical energy with minimal waste, resulting in lower energy consumption and reduced operating costs. This makes them a sustainable choice for businesses looking to improve their energy efficiency and reduce their carbon footprint.

AC gear motors are versatile and can be used in a wide range of applications across various industries. From HVAC systems and industrial automation to food processing and automotive assembly lines, AC gear motors play a critical role in ensuring the smooth operation of equipment and machinery.

In conclusion, AC gear motors offer numerous advantages in terms of precision speed control, high torque output, durability, reliability, efficiency, and versatility. Their widespread use in a variety of applications highlights their importance in the industrial sector. Businesses looking to enhance their operations and improve productivity should consider the benefits of AC gear motors and incorporate them into their equipment and machinery.

- Understanding the Functionality and Components of AC Gear Motors

AC gear motors play a crucial role in various industries and applications due to their functionality and components. In this comprehensive guide, we will delve into the inner workings of AC gear motors to provide a better understanding of their importance and applications.

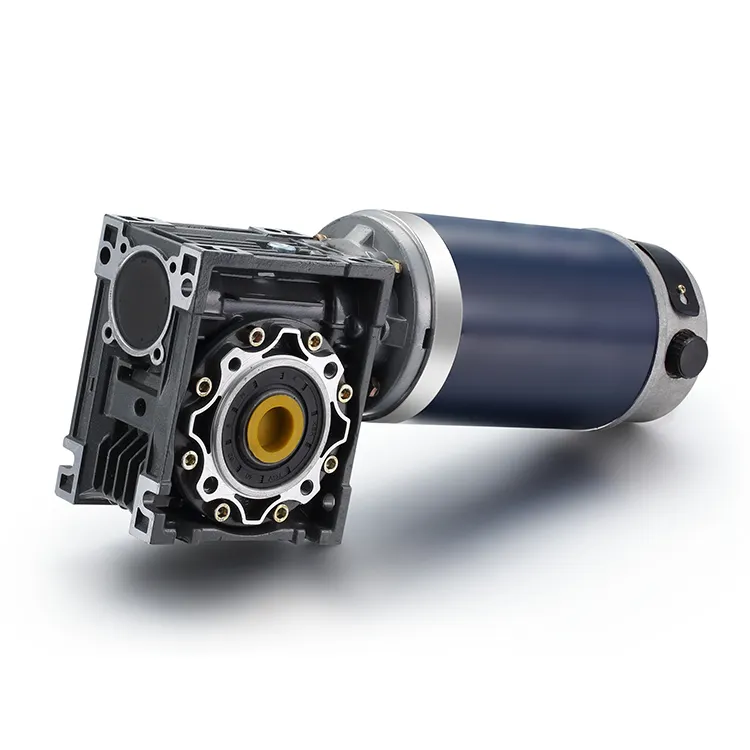

At the heart of an AC gear motor is the combination of an AC motor and a gear unit. The AC motor converts electrical energy into mechanical energy, while the gear unit helps to control and transmit power to different components. This combination allows for increased torque and reduced speed, making AC gear motors ideal for applications requiring precise control and power.

The functionality of AC gear motors is further enhanced by their components, which include shafts, gears, bearings, enclosures, and cooling systems. The shafts in AC gear motors are responsible for transmitting power from the motor to the gears, while the gears help to control the speed and torque of the motor. Bearings are crucial components that support the shafts and reduce friction, ensuring smooth operation.

Enclosures in AC gear motors not only protect the internal components from external elements but also help to dissipate heat generated during operation. Cooling systems, such as fans or fins, play a vital role in maintaining optimal operating temperature and prolonging the lifespan of the motor.

One of the key advantages of AC gear motors is their versatility and adaptability to different applications. From industrial automation and robotics to automotive and HVAC systems, AC gear motors can be found in a wide range of industries and applications. Their ability to provide precise control, high torque, and reliable performance makes them an essential component in various machinery and equipment.

In conclusion, understanding the functionality and components of AC gear motors is essential for maximizing their potential and ensuring efficient operation. By harnessing the power of AC gear motors, industries can achieve greater productivity, reliability, and performance in their applications. Whether in manufacturing, transportation, or any other industry, AC gear motors play a crucial role in driving innovation and advancement.

- How to Select the Right AC Gear Motor for Your Needs

AC gear motors are an essential component in various industries, providing the power and efficiency needed to drive machinery and equipment. Understanding how to select the right AC gear motor for your specific needs is crucial to optimizing performance and ensuring the smooth operation of your systems.

When it comes to choosing an AC gear motor, there are several key factors to consider. The first step is to determine the power requirements of your application. This includes assessing the amount of torque and speed needed to drive your machinery effectively. AC gear motors come in a wide range of power ratings, so it is important to match the motor size and power output to your specific requirements.

Another important consideration when selecting an AC gear motor is the type of gear mechanism. Gear motors can utilize different types of gearing, such as spur gears, helical gears, or planetary gears, each offering specific advantages in terms of torque, speed, and efficiency. Understanding the differences between these types of gear mechanisms can help you choose the right option for your application.

In addition to power and gearing, it is important to consider the environmental conditions in which the AC gear motor will be operating. AC gear motors are designed to withstand a variety of environmental factors, such as temperature fluctuations, moisture, and dust. Choosing a motor that is rated for the specific environmental conditions of your application will help ensure optimal performance and longevity.

Furthermore, it is essential to consider the overall size and mounting requirements of the AC gear motor. Some applications may have limited space available for the motor, so choosing a compact and lightweight option may be necessary. Additionally, the mounting configuration of the motor must be compatible with the machinery or equipment it will be driving.

When selecting an AC gear motor, it is also important to consider the overall efficiency and energy consumption of the motor. Higher efficiency motors can help reduce energy costs and minimize heat generation, leading to improved overall performance and longevity. Choosing a motor with the appropriate efficiency rating for your application can help optimize energy usage and reduce operating costs.

In conclusion, selecting the right AC gear motor for your needs requires careful consideration of power requirements, gearing mechanisms, environmental conditions, size and mounting requirements, efficiency, and energy consumption. By taking the time to evaluate these factors and choose a motor that is well-suited to your specific application, you can ensure the reliable and efficient operation of your machinery and equipment. The power of AC gear motors is undeniable, and by understanding their functionality and selecting the right motor for your needs, you can maximize the performance and longevity of your systems.

- Maintenance and Troubleshooting Tips for AC Gear Motors

AC gear motors are an essential component in many industrial and commercial applications, providing the power and torque required to operate a wide range of machinery and equipment. In this comprehensive guide, we will delve into the functionality of AC gear motors, as well as provide maintenance and troubleshooting tips to ensure optimal performance.

AC gear motors combine the functionality of an AC motor with a gear system, allowing for controlled and precise movement of the output shaft. These motors are commonly used in conveyor systems, elevators, and other applications where a high level of torque is required.

One of the key advantages of AC gear motors is their ability to provide variable speed control, making them ideal for applications where precise control over the speed of the machinery is necessary. This also helps to extend the lifespan of the motor, as it can operate at lower speeds when required.

To ensure the optimal performance of an AC gear motor, regular maintenance is key. This includes checking for any signs of wear and tear on the motor and gear system, as well as ensuring that the motor is properly lubricated. It is also important to regularly check the electrical connections and ensure that the motor is receiving the correct voltage and current.

In the event that an issue arises with an AC gear motor, troubleshooting is essential to identify and resolve the problem. Common issues with AC gear motors include overheating, excessive noise, and vibration. In the case of overheating, it may be necessary to check the ventilation system and ensure that the motor is not operating in a high-temperature environment.

Excessive noise and vibration can be indicative of issues with the gear system, such as worn gears or misalignment. In this case, it may be necessary to inspect the gear system and make any necessary adjustments or repairs. It is also important to check for any loose connections or damaged components that may be causing the issue.

In conclusion, AC gear motors play a crucial role in many industrial and commercial applications, providing the power and torque required to operate machinery and equipment. By understanding the functionality of AC gear motors and following proper maintenance and troubleshooting procedures, you can ensure the optimal performance and longevity of these essential components.

Conclusion

In conclusion, AC gear motors are a powerful and versatile component in various industries, providing efficient and reliable functionality. By understanding their design, operation, and applications, businesses can make informed decisions when it comes to incorporating AC gear motors into their machinery and equipment. Whether it's improving performance, increasing productivity, or reducing energy consumption, the power of AC gear motors is undeniable. So, the next time you're looking to enhance your operations, consider the benefits of incorporating AC gear motors for optimal performance and efficiency.

![]() No.2986 Tiantong South Road, Yinzhou District, Ningbo City, China

No.2986 Tiantong South Road, Yinzhou District, Ningbo City, China

![]() Tel: +86 574 88452873

Tel: +86 574 88452873

![]() Email: support@china-bgmotor.com

Email: support@china-bgmotor.com