BG Motor has been a DC motor manufacturer and AC motor supplier for 30+ years.

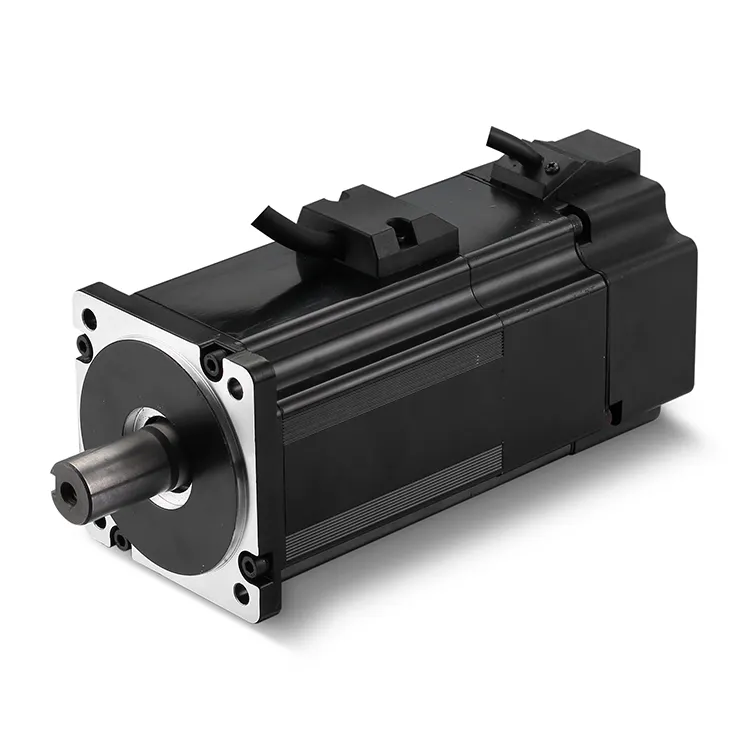

Unleashing The Power Of DC Brushless Motors: A Comprehensive Guide

Welcome to our comprehensive guide on unleashing the power of DC brushless motors. Whether you are a seasoned engineer or a curious hobbyist, this article will provide you with all the essential information you need to harness the full potential of these advanced motors. From understanding the fundamental principles of operation to optimizing performance and efficiency, our guide covers it all. Join us as we delve into the world of DC brushless motors and discover how they can revolutionize your projects.

Understanding the Basics of DC Brushless Motors

DC brushless motors are a vital component in various industries, including robotics, automotive, and aerospace. Understanding the basics of DC brushless motors is essential for engineers, designers, and hobbyists working with these powerful and efficient motors.

DC brushless motors operate on the principle of electromagnetism, utilizing a series of coils and magnets to generate motion. Unlike traditional brushed DC motors, brushless motors do not rely on physical brushes to transfer electrical current to the rotor. This design results in smoother operation, higher efficiency, and less maintenance compared to their brushed counterparts.

One of the key advantages of DC brushless motors is their ability to operate at higher speeds and produce more torque than brushed DC motors of the same size. This makes them ideal for applications where high performance and precision are required, such as in industrial automation and medical devices.

Another major benefit of DC brushless motors is their increased reliability and longevity. Since there are no brushes to wear out, brushless motors can last much longer and operate more consistently over time. This makes them a cost-effective solution for applications that require continuous and reliable operation.

Additionally, DC brushless motors are highly customizable and can be tailored to specific performance requirements. By adjusting parameters such as voltage, current, and winding configurations, engineers can optimize the motor for their specific application, whether it be speed control, position sensing, or torque output.

In terms of control, DC brushless motors are typically driven by electronic speed controllers (ESCs) that regulate the flow of current to the motor coils. This allows for precise control of speed, direction, and torque, making brushless motors ideal for applications that require dynamic and responsive performance.

Overall, understanding the basics of DC brushless motors is essential for anyone working with these powerful and versatile motors. By harnessing the efficiency, reliability, and performance capabilities of brushless motors, engineers and designers can unlock a world of possibilities in their applications.

In conclusion, DC brushless motors are a cornerstone of modern technology, providing high performance, efficiency, and reliability in a wide range of applications. By grasping the fundamentals of brushless motor operation, engineers and designers can unleash the full potential of these powerful motors and drive innovation in their respective fields.

Benefits and Applications of DC Brushless Motors

The first thing that comes to mind when discussing the benefits and applications of DC brushless motors is their efficiency and reliability. These motors are known for their ability to provide high levels of power while consuming minimal energy, making them a popular choice for a wide range of applications. From industrial machinery to consumer electronics, DC brushless motors have become an essential component in many modern technologies.

One of the key benefits of DC brushless motors is their high efficiency. Unlike traditional brushed motors, which rely on physical brushes to transmit power, brushless motors use electronic commutation to control the flow of electricity. This eliminates the need for brushes, reducing friction and heat generation and ultimately improving the motor's overall efficiency. This increased efficiency not only results in lower energy consumption but also extends the motor's lifespan, making it a cost-effective solution for many applications.

Another advantage of DC brushless motors is their reliability. With fewer moving parts and no brushes to wear out, these motors are less prone to mechanical failures and require less maintenance than their brushed counterparts. This makes them an ideal choice for critical applications where downtime is not an option, such as in medical devices or aerospace systems. Additionally, the precise control offered by electronic commutation allows for smooth, consistent operation, further enhancing the motor's reliability and performance.

In terms of applications, DC brushless motors can be found in a wide variety of industries and products. In the automotive sector, these motors are used in electric vehicles and hybrid cars to provide efficient propulsion. In the HVAC industry, they are used in fans and blowers to regulate airflow. In robotics, they are used to control the movement of robotic arms and other devices with precision. The versatility of DC brushless motors makes them a versatile solution for a wide range of applications.

Overall, the benefits and applications of DC brushless motors are vast and varied. From their high efficiency and reliability to their versatility and precision control, these motors offer a multitude of advantages for countless industries and products. As technology continues to advance, the demand for DC brushless motors is only expected to grow, solidifying their place as a key component in the modern world of engineering and innovation.

Key Components and Functions of DC Brushless Motors

DC brushless motors have revolutionized the way we power various devices and machinery, offering improved efficiency and performance compared to traditional brushed motors. In this comprehensive guide, we will delve into the key components and functions of DC brushless motors, unravelling the secrets behind their power and reliability.

At the heart of a DC brushless motor lies the rotor, which is connected to the shaft and responsible for generating the rotational motion. Unlike brushed motors, DC brushless motors do not rely on physical brushes or commutators to switch the currents, making them more durable and maintenance-free. Instead, they utilize a series of magnets embedded in the rotor, which interact with the stator to produce a spinning motion.

The stator is another crucial component of a DC brushless motor, consisting of coils of wire that create a magnetic field when an electrical current is passed through them. This magnetic field then interacts with the rotor's magnets, causing the rotor to turn. By controlling the timing and strength of the electrical currents in the stator coils, the speed and direction of the motor can be precisely controlled.

One of the main advantages of DC brushless motors is their efficiency. Unlike brushed motors, which suffer from energy losses due to friction and sparking at the brushes, DC brushless motors eliminate these issues, resulting in higher energy efficiency and less heat generation. This makes them ideal for applications where power consumption and heat dissipation are critical factors.

Another key feature of DC brushless motors is their ability to provide precise and smooth control over speed and torque. By adjusting the strength and timing of the electrical currents in the stator coils, the motor can be accelerated, decelerated, and stopped with precision. This makes DC brushless motors perfect for applications that require precise motion control, such as robotics and CNC machines.

In addition to their efficiency and precision, DC brushless motors also offer superior reliability and longevity. Without the wear and tear associated with brushes and commutators, DC brushless motors have a much longer lifespan, making them a cost-effective solution in the long run. Furthermore, their maintenance-free design reduces downtime and maintenance costs, further boosting their appeal in industrial applications.

Overall, DC brushless motors represent a significant advancement in motor technology, offering improved efficiency, precision, reliability, and longevity compared to traditional brushed motors. By understanding the key components and functions of DC brushless motors, engineers and designers can unlock their full potential and unleash their power in a wide range of applications.

How to Select the Right DC Brushless Motor for Your Application

DC brushless motors have become increasingly popular in a wide range of industrial applications, thanks to their efficiency, reliability, and performance. In this comprehensive guide, we will delve into the various aspects of DC brushless motors and provide valuable insights on how to select the right one for your specific application.

DC brushless motors are electric motors that operate without the need for a physical commutator, unlike traditional brushed motors. This design feature eliminates the wear and tear associated with brushes, resulting in improved efficiency and longevity. DC brushless motors are also known for their high torque capabilities, precise speed control, and low maintenance requirements, making them an ideal choice for a variety of industrial applications.

When selecting a DC brushless motor for your application, it is essential to consider several key factors. The first factor to consider is power requirements. Determine the power output needed for your specific application, as this will dictate the size and type of motor required. Additionally, consider the operating voltage and current requirements, as well as any duty cycle and speed control specifications.

Another important factor to consider when selecting a DC brushless motor is the mechanical specifications. Consider the physical dimensions of the motor, including the shaft size and mounting options, to ensure compatibility with your application. Additionally, consider the motor's temperature rating and IP protection class to ensure it can withstand the environmental conditions in which it will operate.

Furthermore, consider the motor's performance specifications, such as its speed-torque characteristics, efficiency, and response time. These factors will determine how well the motor will perform in your specific application and can help you achieve the desired level of performance.

In addition to these technical considerations, it is also essential to consider the manufacturer's reputation and the motor's quality and reliability. Look for a reputable manufacturer with a proven track record of producing high-quality DC brushless motors that meet industry standards and regulations. Additionally, consider factors such as warranty and customer support to ensure you receive the necessary assistance in case of any issues.

In conclusion, selecting the right DC brushless motor for your application requires careful consideration of various factors, including power requirements, mechanical specifications, performance characteristics, and manufacturer reputation. By understanding these factors and conducting thorough research, you can ensure you choose a motor that meets your specific needs and delivers optimal performance. With the right motor in place, you can unleash the power of DC brushless motors and achieve success in your industrial applications.

Tips for Maximizing the Efficiency and Performance of DC Brushless Motors

DC brushless motors have become a popular choice in a wide range of applications due to their efficiency and high performance. In order to fully unleash the power of these motors, it is essential to understand how to maximize their efficiency and performance. This comprehensive guide provides valuable tips for achieving optimal results with DC brushless motors.

One of the key factors in maximizing the efficiency of DC brushless motors is proper maintenance and care. Regular maintenance, such as cleaning and lubrication, can help prevent wear and tear on the motor components, ensuring that it operates smoothly and efficiently. In addition, being proactive about replacing worn-out parts, such as bearings and brushes, can help prevent costly breakdowns and downtime.

Another important aspect of maximizing the efficiency of DC brushless motors is ensuring that they are properly sized for the application. An undersized motor may struggle to meet the demands of the load, leading to inefficient operation and potential damage to the motor. On the other hand, an oversized motor may consume more power than necessary, resulting in increased operating costs. By selecting the right size motor for the job, you can optimize performance and efficiency.

Proper installation is also crucial for maximizing the performance of DC brushless motors. Ensuring that the motor is securely mounted and aligned with the driven equipment can help prevent vibration and excessive wear, which can reduce efficiency and shorten the motor's lifespan. Additionally, accurate wiring and proper insulation can help prevent electrical issues that can impact the motor's performance.

In addition to maintenance, sizing, and installation, there are several other factors to consider when maximizing the efficiency and performance of DC brushless motors. For example, controlling the motor's speed and torque through the use of a variable frequency drive can help optimize energy consumption and improve overall performance. Additionally, using sensors and monitoring equipment can help identify potential issues before they escalate, allowing for timely maintenance and repairs.

Overall, by taking a proactive approach to maintenance, sizing, installation, and control, you can unlock the full potential of DC brushless motors and achieve optimal efficiency and performance. With careful attention to these key factors, you can ensure that your motors operate at peak performance levels, delivering reliable and consistent results in a wide range of applications.

Conclusion

In conclusion, DC brushless motors offer a multitude of benefits and applications across various industries. From improved efficiency and reliability to precise control and reduced maintenance costs, these motors truly unleash a powerful performance that can drive innovation and success. By understanding the principles, operation, and advantages of DC brushless motors as outlined in this comprehensive guide, businesses and engineers alike can harness their potential to enhance their products and processes. Embracing the power of DC brushless motors opens up a world of possibilities for creating smarter, more efficient, and more sustainable technology solutions. So, dive in, explore, and let the power of DC brushless motors propel your ideas to new heights.

![]() No.2986 Tiantong South Road, Yinzhou District, Ningbo City, China

No.2986 Tiantong South Road, Yinzhou District, Ningbo City, China

![]() Tel: +86 574 88452873

Tel: +86 574 88452873

![]() Email: support@china-bgmotor.com

Email: support@china-bgmotor.com